Government officials build massive chicken ‘slow cooker’ in southeast Washington

Read

Lynne Carpenter-Boggs composted her first hog back in 1998, in Minnesota.

“It was fairly ambitious,” she says. “It [composting animals] was fairly new at that time. So, composting is decomposition, microbial decomposition of organic materials, and you can use just about any organic material.”

Since her first hog, the Washington State University soil scientist, based in Pullman, has become one of the top experts in the nation for how to compost large amounts of domestic animals in outbreak or disaster situations. And this year, she’s traveled across the U.S. to ply that trade in the wake of the worst highly pathogenic avian influenza outbreak the U.S. has remembered.

Tons of wild birds have fallen sick: geese, owls, pelicans and raptors. It’s also spilling over to mammals like foxes, bears, skunks, seals and even a bobcat, says Amber Itle, the state veterinarian with the Washington State Department of Agriculture. And the virus isn’t showing signs of weakening.

“This particular strain of avian influenza is super pathogenic – lots of birds get sick, and a lot of birds die,” Itle says. “Different species migrate at different times. As more and more birds migrate, we’re increasing the viral load in the environment at those waterways. It’s like this domino effect – there is more and more chance for birds to get sick or carry the virus to the next place.”

Many of these migratory pathways overlap across the globe. And so this highly pathogenic stain has now spread nearly everywhere, Itle says. And spring migration is coming.

Highly pathogenic avian influenza has hit backyard flocks as well as commercial chicken operations across the United States. (Credit: Karla Salp / Washington State Department of Agriculture.)

Outbreak facts

So far, about 58 million birds have died or been euthanized because of this outbreak across the U.S. – both hundreds of backyard and commercial flocks – since last fall. In the Northwest, 1,018,302 birds have died in Washington state and 1,798 birds have died in Oregon.

Many of those flocks have had to be depopulated, or killed, per US Department of Agriculture regulations.

The outbreak across the U.S. is so bad, egg and chicken stocks are running low for consumers in limited areas. Many people are posting pictures on social media of high egg prices or dwindling stocks of eggs on store shelves.

“I’m dying, how expensive is that?” says Teresa Agtuca, of Maple Valley, Washington, while staring at cage-free egg prices for nearly $10 a dozen at a Fred Meyer store in a short video for family and friends. “I will really have to plan ahead with my egg needs, they may need to be a weekend treat until prices come down.”

Egg producers in the United States say they themselves are concerned over some pockets of high prices.

“It’s important for consumers to know that egg farmers don’t set the price of their eggs,” said Emily Metz, president and CEO of the American Egg Board – a national marketing organization for U.S. egg farmers. “They [prices] are set on the commodities market in Chicago. We’re also coming off of peak demand during the holidays, everyone bakes and cooks. The second thing is that inflation has also been a factor. The third thing is inputs – feed, fuel costs – have been really up. The fourth thing is bird flu.”

There are usually around 320 million laying hens in the U.S., she says. Recently, flocks have been down about 6% to more like 300 million layers.

“As a result we are seeing some very local shortages,” she says.

“We’re not seeing panic buying. And those shortages are being corrected very quickly.”

There are also shortages in states where new regulations about cage-free eggs have come to bear – like in California and Colorado.

Thirty percent of the U.S. commercial flock are cage free — but now there’s higher demand for cage-free eggs, Metz says. She says the industry is trying to build new barns but is running up against tight steel and lumber supplies.

Metz says commercial egg laying operations are being hyper vigilant to keep bird flu at bay, but it attacks birds without discrimination. She says affected growers are getting faster at recovering from bird flu – back several years ago it could take nearly a year to repopulate a farm. Now, she says, farms are up and running in as little as three to six months with a coordinated effort of federal, state and local agency responders.

But veterinarian Itle says viruses like avian influenza can become a large problem, when they get into a large population of animals.

“When we have these types of large commercial systems, there are tradeoffs to that,” she says. “We have safe, inexpensive food for everyone. But food security wise, when we have an outbreak like this – when we have hundreds of farms, with millions of chickens each – it’s a huge impact. There is going to be some trickle down, and it’s going to take months to recover.”

‘Slow cooker’

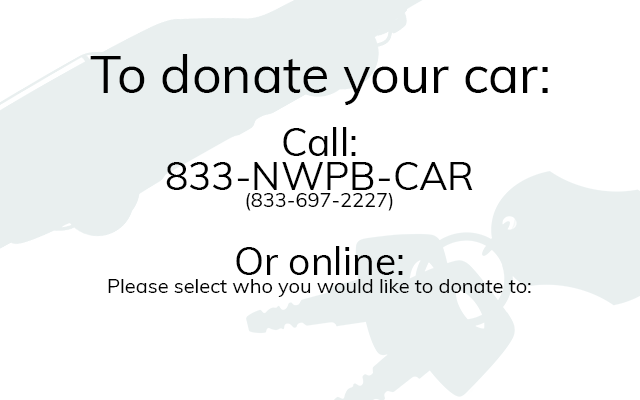

One of the hardest parts of the entire outbreak near Pasco is the disposal of so many chickens. But, composting has helped officials get through the mess, says soil scientist Carpenter-Boggs.

“Composting is only something that happens en masse,” she says. “It stimulates incredible amounts of microbial action and generates heat – what’s really remarkable is that heat production.”

This is how it works: First, the chickens are depopulated. In backyard flocks using carbon dioxide, or CO2. In the big commercial populations, using whole-house CO2. Officials wrap the whole chicken house in plastic and then congregate the chickens in one area while they flood the gas in very quickly, so most chickens die right away.

“It’s so sad, as a veterinarian it just never gets easier,” Itle says. “We want to do the right thing; it’s really sad, and it’s really hard, but we want to do right by the animal at the end of the day. These are living creatures that deserve a respectful death.”

Depopulation in this way is also very expensive: A tanker full of CO2 costs around $10,000, and you need two per house, Itle explains. The state usually picks up the bill, she says.

Then, the dead birds are folded in like a morbid wedding cake into large windrows that can reach 7 feet tall and several hundred feet in length. Some of the larger facilities could have several miles of windrows after workers complete building them.

Sometimes this is done outside, but sometimes it’s done right inside the chicken houses. This helps protect against scavengers or further contamination, Carpenter-Boggs says. It also keeps most of the action out of sight, she says.

Birds, litter, unused feed, eggs, manure – all has to be composted. It also has to be kept away from groundwater, or pooling of water.

“It really depends on the farm, how much stuff is in those houses,” Itle says.

In these large commercial chicken operations, hundreds of thousands of cubic yards of materials like straw, chopped up corn stalks or wood chips are layered below the pile and within the pile. An additional layer is put on top to insulate the pile and keep the whole thing secure.

“Particularly in the case of disease outbreaks we don’t have to break apart those bodies even,” Carpenter-Boggs says. “We stimulate this very rapid decomposition and heat production.”

The chickens are “cooked” for at least two, 14-day periods. They need to get up to 131 degrees Fahrenheit, for at least three days in a row in both periods.

Experts monitor the temperature at 18 inches and 36 inches of depth in 10 places in every windrow.

“It’s a slow cooker,” she says, with a slight chuckle. “Kind of a dryish crockpot. Viruses are very well managed in composting.”

Surprisingly, Carpenter-Boggs says, if the process is done right there’s little to no stink.

“A lot of people worry about the odors,” she says. “One of the things we look at when we are even identifying where the composting is going to be done is: Where are the neighbors, and what direction does the wind blow?”

But she says, once things are in the compost pile – neighbors shouldn’t really notice.

“We don’t want it to be rotting,” she says. “Rotting is very different from good composting.”

Over the top of the entire pile, officials layer plant material, she explains. Plant material should not have offensive odors to it.

“It’s not only about not offending humans with those orders, but we don’t want to attract scavengers either,” she says.

Decomposting meat can release ammonia. Other chemicals with names like putrescine and cadaverine can also be made by the stew, but they are usually absorbed and blocked from nostrils by the layer of plant material on top, Carpenter-Boggs says.

Large equipment is often used to turn, move and form the material in large-scale compost piles. (Credit: Karla Salp / Washington Department of Agriculture)

Feathers, bones or beaks

When the compost is finished ‘cooking’ — there are little to no distinguishable feathers, bones or beaks.

And officials can screen the whole pile to remove any larger pieces like wood chips. Then growers can apply the compost to fields.

“There is little evidence that there are chickens in there, it looks like any other compost,” Carpenter-Boggs says.

Larger animals and older animals with denser bones – like cattle and horses – can take longer to compost.

The top advantage, other than disposal of the animals, is with proper composting the virus is killed, Carpenter-Boggs says.

“You don’t have to move the carcasses around [to another location],” she says. “The management of the disease is very effective.”

There are no rules about where growers can or can’t spread the compost after it is properly “cooked,” says state veterinarian Itle.

It may be grim work, but the ability to clean up these massive outbreaks is important, Carpenter-Boggs says. And even people with backyard flocks, or a sick horse, appreciate the ability to take care of their animals ‘til the last in a fairly inexpensive way.

“It can be done on the farm,” she says.