The dirty work of owning mason bees

Listen

(Runtime 3:58)

Read

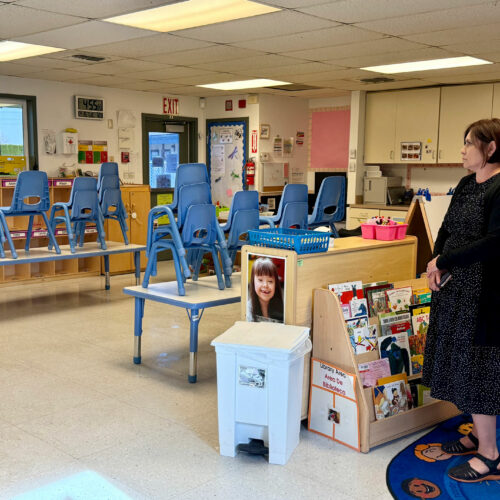

Every October, in the backyard of a Bothell home, a team of workers swarm around millions of blue orchard mason bees to harvest the hibernating insects.

The company, Rent Mason Bees, quickly takes apart and cleans the wooden nesting blocks that gardeners and farmers across the state use in the spring to house these tiny pollinators. The company offers this service as part of its mason bee rental program.

“A lot of people say, ‘Well, are we renting a bee?’ No, you’re releasing the bees and renting the nesting blocks,” said Thyra McKelvie, the pollination program educator for Rent Mason Bees.

Mason bees are solitary bees. Instead of heading back to a busy and populated hive, a single bee finds a hollow hole somewhere in its environment to nest in. That can be anywhere from an old nail hole in a fence post to a beetle hole in a pine tree.

As gardeners and farmers have taken an interest in housing these bees, including the blue orchard mason bee, people have begun creating “mason bee hotels.” The bees crawl into these and deposit their larvae, which cocoon themselves for the winter.

But these man-made nesting blocks require a bit of human intervention to keep the bees safe and healthy for the next season.

“People buying these nest blocks and hoping that they’re providing habitat for bees can do more harm than good,” said Bri Price, who is Washington State University’s Bee Program extension coordinator.

Every autumn, nesting material has to be opened up and cleaned. Otherwise, Price said predators and parasites will find their way into nest cavities and wreak havoc.

That’s why Rent Mason Bees cleans the nesting blocks their customers use.

In the autumn, renters ship their wooden nesting blocks back to the company. Watts and his team, using the aid of specially crafted machines, disassemble the small wooden blocks, empty them of the mason bee cocoons and whatever else might have crawled in.

The wooden blocks that bees nest in are emptied by the one of a kind Bob Harvester machine. (Credit: Lauren Gallup / NWPB)

Tiny bee cocoons, packed gray mud, live earwigs, yellow pollen mites and brown Houdini fly poop all come out of the nests.

“There’ll be ants, lots of creepy crawlies when you open up your block,” McKelvie said. “You never know what you’re gonna find.”

Then, the blocks then go through both a pressurized air chamber and an open flame to clear out and sanitize them from any remaining fungi and predators. Watts said his cousin and colleague got the idea to run the blocks through fire from the Discovery Channel docudrama “Moonshiners.”

After the blocks are clean, the bee cocoons, which are hardy and waterproof, get a spa treatment. Workers sift them through a screen to loosen off dust, and then soak them in a bleach-water solution (called a bee bath). They’ll then mist them with clean water for a final rinse.

Watts said one of his employees will be working every day through November to clean all the bee cocoons. The company harvests about 3 million each year.

The bee cocoons are dried out overnight and sorted to ensure there are only healthy cocoons. They are then divided by where they came from, placed into plastic containers and then stored at 40 degrees to hibernate all winter. In early spring, renters will get clean nesting blocks and bee cocoons in time for pollination.

Watts’ father started the company in the 1960s, selling another kind of solitary bee — leafcutters — to farmers who were interested in them for pollination. About 10 years ago, he started renting out the mason bees to diversify the business.

“They’re very hard to raise, so our growth is not as fast as we’d like, but it’s getting there,” Watts said.

Watts said he has seen success for people using the mason bees to help pollinate crops. That success has been measured by bigger yields. His company works with some almond growers in California, who like the bees for their ability to pollinate at lower temperatures.

The Washington State Department of Agriculture doesn’t track how many farms use mason bees, but Katie Buckley, the pollinator health coordinator for the department, said her understanding is that there’s only a handful. Still, that is more than it was a few years ago, as farmers explore diversifying their pollinators.

Price, with WSU’s Bee Program, said research has shown that using mason bees with honey bees can help bolster crop production. One study found that when the bees were both pollinating in cherry orchards, the amount of flowers that bloomed into fruit increased by around 15%.

Besides managed bees, farmers around the state are now working to attract native bees to their crop.

“There has been a lot of interest, and I know a lot more growers, who are doing things like putting in cover crops under their orchards or hedgerows to bring in the native pollinators that are already there,” Buckley said.

There are over 600 bee species native to Washington, said Karen Wright, the pollinator taxonomist for the department of agriculture. Other than that, she said not much is known enough about native bees in the state.

The department is looking to change that. They started a new program called the Washington Bee Atlas, staffed by volunteer community scientists that the department trains on how to track where bees live, where they nest and what they pollinate.

“We’re just starting to come up with the data to tell us more about all the other non-managed native bees in the state,” Wright said.

One goal of that program is to figure out which native mason bee species are helping with orchard pollination.