Worms eating airport deicer fluid could be greener approach to airline waste

Listen

(Runtime 0:57)

Read

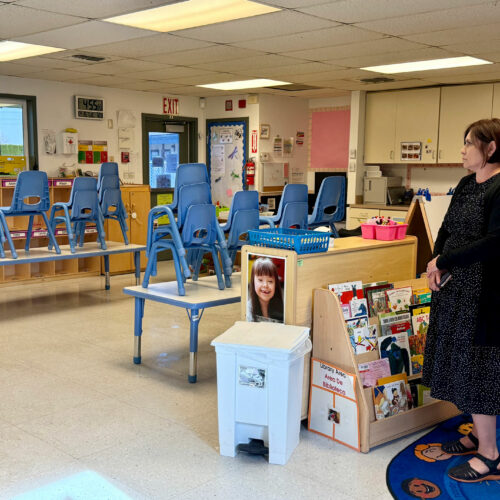

To safely fly when it’s cold out, special fluid keeps planes from icing over. However, spraying the fluid creates a lot of waste. Now, airport leaders in Pasco, Washington have turned to an unusual deicer disposal technology: worms.

When the Tri-Cities Airport was smaller, it sent deicing wastewater to the City of Pasco for disposal. In recent years, the airport has grown, adding more terminals and bigger planes, therefore using more deicer, which contains ethylene glycol and propylene glycol which prevent windshields from freezing.

“It was just getting to the point where the plant was struggling with the load we were delivering,” said Buck Taft, airport director. “We had grown so much.”

Taft needed a new solution to get rid of the growing amount of deicing glycol. He remembered a talk he’d heard about worms eating up wastewater at wineries and food processors. Taft wondered: Could it work at the airport?

After some investigation, airport officials and the company behind the wormy technology, BioFiltro, began a pilot project. If it all works, the waste eventually will be turned into fertilizer, also known as worm castings.

“This could be a way for us to be sustainable,” Taft said.

The pilot project will cost about $45,000, some of which will be deducted from the full system if the project is viable, Taft said.

The worms in the pilot project live in a 90-square-foot semi-truck container. The filters in the container have layers of drainage basins, crushed rock, wood shavings, microbes, as well as earthworms.

Wastewater flows onto the top of the system and filters down with the help of gravity, said Patrick Beckett, BioFiltro’s vice president of quality and research and development.

“We use a common composting worm, Eisenia andrei. I think a lot of people would refer to it as a red wiggler, something you can use for home composting,” Beckett said. “What’s interesting is what the worm eats and what it poops out are different. The worm castings have a lot of benefits for soil health and for plant growth.”

The worm castings collect in the filter from the point the system is inoculated, Beckett said. The castings fill up the filter faster in different systems and it’s unclear how often they’ll need to change the filter for this new application. Beckett said he estimates it could be every two to three years, if winery systems are a clue.

Once removed from the filter, the worm castings and woodchips mature for up to 60 days, Beckett said.

“After that you have a very nice, stable vermicompost mixed with wood shavings. One can either apply the mixture or screen out the shavings to obtain pure worm castings,” he said.

BioFlitro tested the deicing glycol, Beckett said, and it won’t harm the worms.

Nevertheless, this new application has its challenges. The wastewater from the airport is more nutritionally imbalanced than other systems the company has worked on, Beckett said. It has a high carbon-to-nitrogen ratio, which has to be balanced to make the worms happy. So, BioFiltro is adding nutrient supplements to the wastewater.

It’s a lot of trying and learning from tests, he said.

“We’re kind of having to consider some ways to operate it that you don’t have to do for a lot of our traditional client base. As you do those things, you just get to understand your own technology better,” Beckett said.

If the program is successful after about six months, airport officials said they plan to use worms to eat up the deicing wastewater – something Taft said he hopes could be an example for other airports across the country.