Robotic Future For Apples May Be Coming, But Not Quite Yet

Right now, your apples are harvested by humans. But Washington may soon face a shortage of apple pickers: as soon as 2021, according to Washington State University economist Karina Gallardo. The labor pool is shrinking with tougher immigration enforcement and a growing Mexican economy.

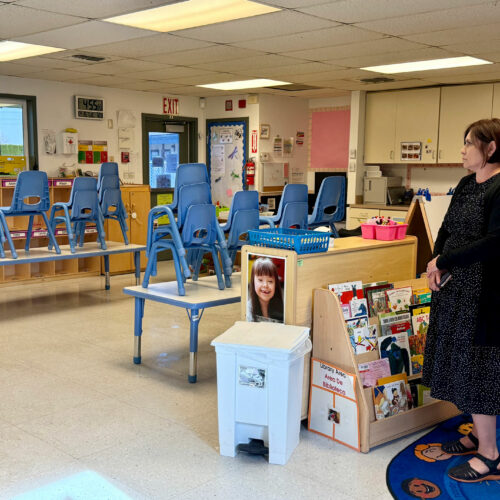

The solution could be automation – as in robots. But don’t expect to see them soon. Karen Lewis, who studies tree fruit with Washington State University, lays out the challenges an apple-picking robot would face:

“That robot needs to find that apple, adhere to it, detach it, and place it into some kind of conveyor system. That’s a big task,” Lewis says. “Often the challenges are the vision system – being able to see every apple.”

Many things that humans do easily, like pick things up and move across the ground, are difficult to replicate with machines. A human arm is a complex system of bones, muscles, and joints. Even getting a robot to move is difficult. Orchards aren’t as robot-friendly as a factory or warehouse.

“This isn’t a slick piece of cement,” Lewis says. “These are outdoor conditions. It’s windy, it’s rainy, it’s dusty, it’s hot and it’s cold.”

Lewis says there are only a few labs in the world developing apple-picking robots. Other possible solutions? Tools to make human pickers more efficient. Companies like Automated Ag in Moses Lake are working on those.

Moving to a more automated apple industry could mean changes to the industry’s basic economic model. Right now, Lewis says, tree fruit growers own all their land and their equipment, and hire their own employees. But automated orchards could look more like the corn or potato industries: apple orchards would contract out to companies with specialized equipment.

And, Lewis says, that might stop small growers from losing out in a changing market.

“If we choose a new business model, then it ought not to exclude people the way other technologies have in the past. In the tree fruit industry, these guys own their equipment,” Lewis says. “If we change the business model, they might not have to buy it, they might not have to lease it, they might just have to contract that service.”

What does this all mean for the people who work in the industry, picking, storing, and packing tree fruit? Karina Gallardo is optimistic.

“If there is a surplus of labor – and I believe that will not be the case – at some point the economy will find an equilibrium,” Gallardo says. “People will find other job opportunities.”

Lewis thinks that apple picking might become a position requiring more skills and education, but sees training and education opportunities for current workers.

“There are key people in those positions that we need to get into courses and programs that will enhance their skills so they can stay in this industry,” Lewis says. “We want to grow our own, we want to hire within, we want to educate within, but tree fruit is an industry that will always be attracting the group of people who studied math and science.”

Significant automation may be a long way out for the industry, but tree fruit growers are already talking about it – and preparing for it. Apple picking robots were tested in Prosser earlier this month.

Copyright 2016 Northwest Public Radio

Related Stories:

Blueberry bust: Hundreds-of-millions-of-dollars blueberry biz in the Northwest and Canada act as one, tariffs could complicate the relationship

Snow melts in drops off bare blueberry bush twigs at a sprawling farm in Franklin County in Washington state. (Credit: Anna King / NWPB) Listen (Runtime 2:47) Read At one

What’s fuzzy, cute and sold out? Chicks

As egg prices surge, baby chicks have been selling out across the region — and the country. (Credit: Susan Shain / NWPB) Listen (Runtime 3:59) Read The first person showed

Searching for sage grouse: Looking for a chicken-sized needle in south-central WA

Seth Hulett, Audubon Washington’s senior program manager of the Columbia Plateau, searches through his spotting scope for sage grouse. (Credit: Courtney Flatt / NWPB) Listen (Runtime 4:12) Read In south-central